Husky Webinar│Blood Collection Tube Manufacturing: Trends, Insights and Opportunities

View this email in your browser |

|

|

| What are the growth opportunities in the medical plastics market?

|

|

According to an analysis report by Research and Markets, the global medical plastics market was valued at US$24.672 billion in 2019 and is expected to reach US$44.67 billion by 2027, with a compound annual growth rate of 7.7% from 2020 to 2027. Behind the interesting data is a significant and long-term development opportunity for the field created by the perfect "storm effect" of many factors. For example, there are still short-term and long-term supply shortages in the supply of key medical devices around the world; in order to solve the local production gap in each country, the localization trend of medical manufacturing is unstoppable; the new crown epidemic, population aging and self-medication are sweeping the world. And the increase in government medical care spending, driving the demand for medical plastics to gradually rise...

|

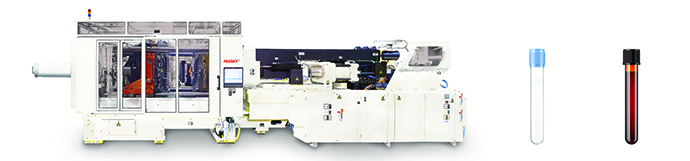

| How easy is it to enter and scale up in the blood collection tube market? Husky experts are here to discuss the trends, insights and opportunities you’ll want to consider.

|

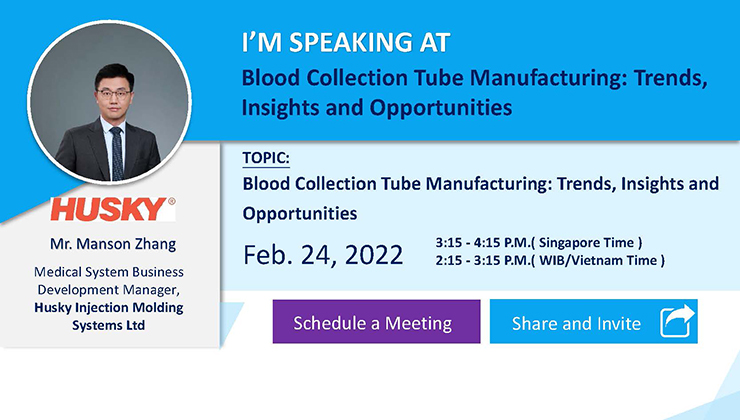

| On Feb.24, 2022, from 15:15 to 16:15(Singapore time), Manson Zhang, a senior expert in Husky's Asia-Pacific medical business and solutions, was once again invited to the Ringier live broadcast room. In this webinar, Manson will focus on the interpretation of the market and regulatory framework, starting from the design specifications and requirements of blood collection tubes, and discuss with you the feasibility of entering the market of blood collection tube manufacturing. What are you waiting for? Sign up for attending the webinar now!

|

|

| Who will attend? |

| ● Technical, R&D, production, operation managers/heads and executives in mature and emerging medical device manufacturing companies

● Audiences from other industrial segments (e.g. beverage package producers, etc.) who have intention to enter into the medical device business or have an interest in medical device manufacturing by means of injection molding.

|

| What attendees will learn:

|

● Medical device market trends – globally and in SEA region

● Introduction to major consumable medical devices/applications along with key production processes

● Typical requirements for the blood collection tube business and key considerations of manufacturing

● IMedical equipment regulatory environment

● IAssess the business entry risks, rewards and pre-requisites

|

| Speaker

|

|

Mr Manson Zhang

Manson Zhang has 10 years’ experience in injection molding, having joined Husky as a product specialist for aftermarket tooling, followed by a business advisor role for injection molding systems for six years, covering the North Asia region.

With strong knowledge in plastic injection molding, Manson supports customers application development projects, as well as business case analysis. He has excellent knowledge of end-to-end application development and helps working together Husky Medical System solutions, involving industry partners when required, to provide turnkey packaging solutions. His guidance and expertise enables existing and prospective customers looking to expand their business, or entering medical manufacturing, providing both technical and business solutions.

Now based in Husky’s Asian headquarters in Shanghai, Mason supports the medical systems business for Asia Pacific, working with existing and prospective customers looking to expand their business, or enter medical manufacturing, providing both technical and business solutions. |

|

|

| Sign up for other upcoming Husky webinar: March 22 | Top trends and emerging technologies in preform-based PET packaging: How to maximize production, efficiency, and competitiveness in the coming decade

|

| About Husky

|

| Team Husky comprises more than 4,300 dedicated people worldwide, focused on building success and profitability for our customers, who operate in over 140 countries.

The headquarters and main manufacturing facilities are located in Canada, with additional manufacturing facilities in the U.S., Luxembourg, Switzerland, China and the Czech Republic. Plus, three technical centers in Japan, Luxembourg and Shanghai, as well as a global network of locations throughout the United States, Latin America, Europe, the Middle East, Africa, Asia-Pacific, China, Australia and India.

Husky builds, installs and supports the world’s most comprehensive range of injection molding systems and equipment, including machines, molds, hot runners, auxiliaries and integrated systems. And, Husky backs them with strong warranties and available extended protection plans, as well as personalized assistance from 600 representatives in 40 service and sales offices.

|

|

|

|

|

|

|